The main features

• this machine is used for ultra-finishing single and double row centripetal ball bearings, single and double row angular contact balls, peach shaped sweeping groove, peach shaped groove half oil, single and double lined aligning center bearings, convex and concave inner raceway, thrust ball bearing groove, thrust spherical roller bearing inner raceway.

• this machine adopts the clamping method of centering the inner hole and pressing the end face, and the workpiece has high turning precision.

• all types of bearing inner ring grooves are completed at one station. Single and double grooves are processed at one datum level through servo motor Angle transformation, effectively improving product quality and processing efficiency.

• the Angle adjustment and swing amplitude of the two channels of the peach shaped little bearing are directly controlled by servo motor, without manual Angle check.

• the workpiece is superfine at the simplex, with coarse whetstone and fine secondary pressure. Whetstone consumption automatic compensation, whetstone too short alarm.

• the workpiece spindle is lubricated by oil mist. The workpiece speed and oscillation frequency are controlled by frequency converter.

• the machine is controlled by Siemens 828D system. The system is stable and reliable, and the parameter setting is input by the touch screen, which is convenient for debugging and management.

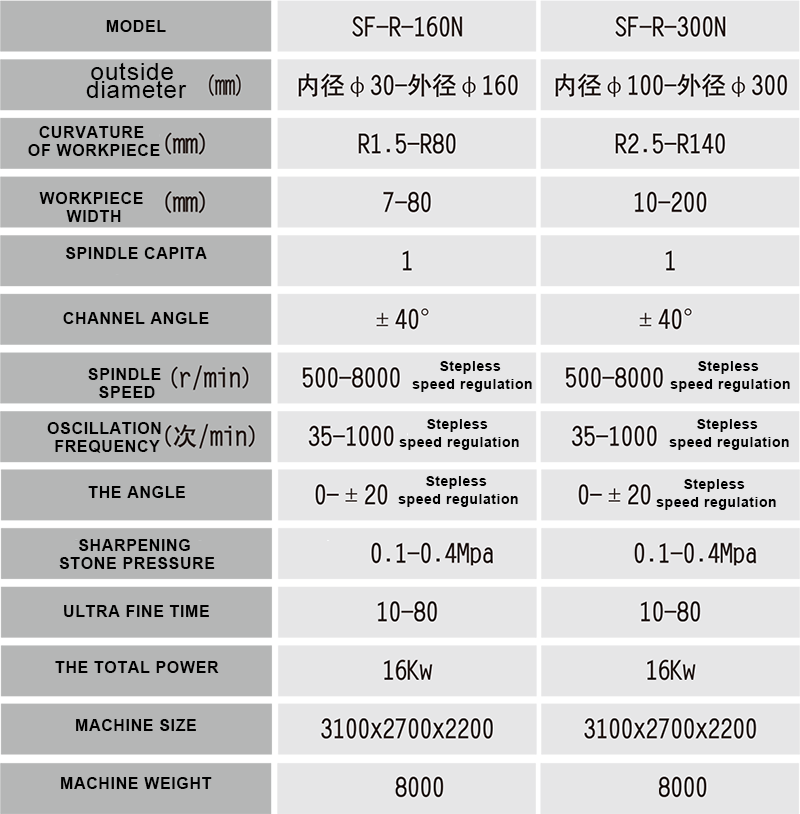

Technical parameters